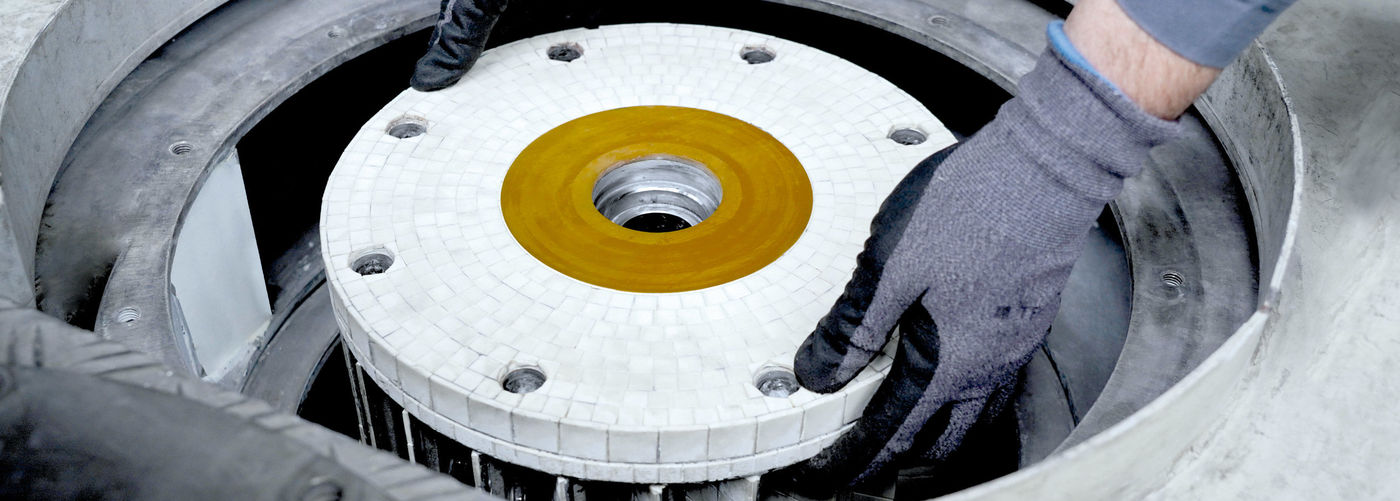

Because the drive of the Stratoplex air classifier is fitted underneath the classifying zone and the feed product is fed centrally from above, the result is an optimum distribution and dispersion of the product. The feed product is charged by means of the feed unit via the product intake to the centrifugal plate of the classifying wheel, where it is distributed uniformly and then catapulted radially towards the baffle ring. The feed material is deflected by the baffle ring and routed downwards into the classifying zone.

The classifying air enters the spiral housing and flows through the helical vanes of the vane ring and the classifying wheel in centripetal direction. The fines portion is removed thereby from the feed material as it gravitates downwards in the classifying zone, i.e. the zone between the vane ring and the classifying wheel.

The fines, extracted as a function of the cut point set on the classifier, are entrained in the classifying air and flow towards the fines discharge. The fines must be separated from the classifying air in a downstream collection device (cyclone, filter). The coarse material is rejected by the classifying wheel and falls into the lower section of the classifier as the result of gravity.

The coarse material discharge must be air-sealed by means of a rotary valve. Rinsing air, either drawn in automatically or supplied under pressure, prevents unclassified product from migrating into the fines through the gap between the classifying wheel and the labyrinth seal. The classifying wheel is usually driven via a V-belt drive with a fixed transmission ratio; the classifier speed can be set by means of a frequency converter. The classifier is delivered complete with filter, fan and cyclone.